Corrosion-resistant chrome-nickel TMK-C alloy is designed for the production of casing and tubing used for wells construction in oil and gas fields with high content and partial pressure of H2S and СО2 in the extracted product.

Application area of TMK-C alloy

- Ambient temperature up to 235° С

- СО2 pressure more than 0.014 MPa

- H2S pressure more than 3.45 MPa

- High chlorides content

- Low рН

Short chemical composition of TMK-C alloy

|

С, % |

Cr, % |

Ni, % |

Mo, % |

S, % |

P, % |

|

≤ 0.02 |

24 - 27 |

29.5 – 36.5 |

2.5 - 4 |

≤ 0.01 |

≤ 0.03 |

Mechanical properties of TMK-C alloy pipes

|

Yield strength σ0.2, MPa |

Tensile strength σв, MPa |

Elongation δ, % |

Charpy absorbed energy at 0 ⁰С, J/cm2 |

|

|

longitudinal samples |

transverse samples |

|||

|

758 - 965 |

≥ 793 |

≥ 12 |

≥ 60 |

≥ 40 |

|

Shear area in longitudinal samples, % |

Hardness HRC |

|

≥ 70 |

≤ 32 |

Production flow chart of TMK-C alloy pipes

|

Hot pressing of semi-finished product |

→ |

Cold rolling of pipes and coupling stock, NDT |

→ |

Couplings production, threading, make-up of "TMK UP PF" Premium connection, hydrotesting |

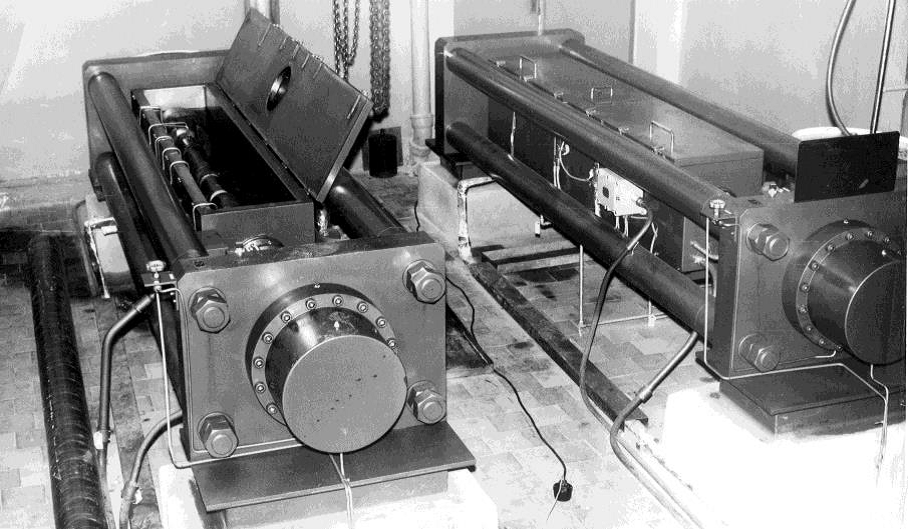

Conducted bench test of pipe sample at combined loading in corrosive environment

External view of the bench for pipe samples testing at combined loading in corrosive environment

Test sample: two TMK-C alloy short pipes 88.9 х 6.45 mm in size coupled with «TMK UP PF» Premium connection

Test conditions:

- Test solution inside the sample: 5% NaCl + 0.5% CH3COOH

- H2S pressure: 1.47 MPa

- СО2 pressure: 1.47 MPa

- Test pressure inside the sample: 73.5 MPa

- Sample bending corresponds to 13.1° per 10 m

- Sample tensile load: 1 076 kN

- Test temperature: +110° С

- Test duration: 720 hours

Successful result: No leakage of liquid and gas, no lubricant extrusion from threaded connections of sample, no pressure drop in sample were observed during the 720 hours test under combined load of internal pressure of test solution saturated with H2S and CO2, axial tension and bending at temperature of + 110° C. During visual inspection of disassembled connections no gallings and defects on thread surface and on sealing elements were detected, which could lead to connection tightness loss under actual operating conditions.

Conducted temperature cycle test of pipe sample

External view of the temperature cycle test bench with pipe sample installed

Test sample: two TMK-C alloy short pipes 88.9 х 6.45 mm in size coupled with «TMK UP PF» Premium connection

Test conditions:

- Nitrogen pressure inside the sample: 76 MPa

- Sample bending corresponds to 13.1° per 10 m

- Minimum water temperature in bath: 20° С - 25° С

- Maximum water temperature in bath: 90° С - 95° С

- Number of temperature change cycles from minimum to maximum and vice versa: 100

- Test duration: 720 hours

Successful result: No nitrogen leakage, no lubricant extrusion from threaded connections of sample, no pressure drop in sample were observed during the 720 hours temperature cycle test under combined load of internal pressure and bending with hundred times temperature change. During visual inspection of disassembled connections no gallings and defects on thread surface and on sealing elements were detected, which could lead to connection tightness loss under actual operating conditions.

Conducted bench test of pipe samples in the gas field

External view of the gas field bench with pipe sample installed

Test sample: two TMK-C alloy short pipes 88.9 х 6.45 mm in size coupled with «TMK UP PF» Premium connection

Test conditions:

- Test solution inside the sample: 5% NaCl + 0.5% CH3COOH

- Gas directly from the well is used for testing, with 33% H2S and 17% CO2

- Test pressure inside the sample: 61.2 MPa

- Sample tensile load: 799.7 kN

- Test duration: 720 hours

Successful result: No leakage of liquid and gas, no lubricant extrusion from threaded connections of sample, no pressure drop in sample were observed during the 720 hours test under combined load of internal pressure of test solution saturated with H2S and CO2 and axial tension. During visual inspection of disassembled connections no gallings and defects on thread surface and on sealing elements were detected, which could lead to connection tightness loss under actual operating conditions.

The developed pipe range from TMK-C alloy

|

Pipe type |

Outside diameter, mm |

Wall thickness, mm |

Grade |

Premium connection |

|

Tubing |

88.9 |

6.45 |

110 ksi |

TMK UP PF |

|

114.3 |

6.88 |

|||

|

Casing |

114.3 |

7.37 |

||

|

127 |

7.52 |

|||

|

177.8 |

9.19 |

|||

|

177.8 |

10.36 |

The pipe range from TMK-C alloy under development

|

Pipe type |

Outside diameter, mm |

Wall thickness, mm |

Grade |

Premium connection |

|

Casing |

168.28 |

10.59 |

110 ksi |

TMK UP PF |

Contacts

E-mail: cra@tmk-group.com

In case of any questions regarding performance, technical parameters of TMK-C alloy and for purchasing of pipes please call:

+7 (495) 775 7600, ext. 2452 (Vitaly Petrochenko), 2756 (Pavel Stepnov)